use of notch in impact test|notched bar pressure test : OEM The keyhole and U-notch are used for the testing of brittle materials such as cast iron and for the testing of plastics. The V-notch specimen is the specimen of choice for weld testing and is the one discussed here. Body Fantasies Signature Fresh White Musk Fragrance Body Spray, 236 mL. 432. Pickup Delivery 1-day shipping. $6.97. $3.07/100g. Body .

{plog:ftitle_list}

WEB55%. Vestido Midi Kímika Buriti Rosa. R$ 554,00. R$ 249,30. 4x de R$ 62,33 sem juros. Ver mais produtos. Uma moda feminina que mescla tendências sem perder suas raízes. Acesse e conheça a essência das peças produzidas pela Kímika.

u notch testing

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .The keyhole and U-notch are used for the testing of brittle materials such as cast iron and for the testing of plastics. The V-notch specimen is the specimen of choice for weld testing and is the one discussed here.The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

The V-notch, characterized by its sharp angle, induces a higher stress concentration. It is ideal for testing the toughness of ductile materials like steel used in welding. In contrast, the U-notch, with its rounded profile, is .

notched bar vs impact bar

notched bar test

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a . Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .

For drop-weight impact tests and dynamic tear tests, a weight is guided by rails and dropped directly onto a test specimen from above. For each type of impact test, a notch is cut into the test specimen, forcing the fracture .

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test.Charpy test sample with a notch. In mechanical engineering and materials science, a notch refers to a V-shaped, U-shaped, or semi-circular defect deliberately introduced into a planar material. In structural components, a notch causes a stress concentration which can result in the initiation and growth of fatigue cracks. Notches are used in materials characterization to .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D .The V-notch maker and impact test machine are displayed in Fig. 1.4 [8]. The impact strength is determined by the loss of energy of the pendulum as determined by precisely measuring the loss of height in the pendulum's swing [9]. Researchers also defined impact strength as the tendency of polymer composites to endure high-energy impact without .

ups drop test specifications

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.

Mechanical testing - Notched bar or impact testing - Part I. The previous article looked at the method of Charpy-V impact testing and the results that can be determined from carrying out a test. This next part looks at the impact testing of welds and some of the factors that affect the transition temperature such as composition and microstructure. ASTM D256 outlines the Izod impact test for plastics, emphasizing specimen preparation and machine calibration for accurate impact resistance data. . In order to do a notched Izod test, a precise notch is cut into the specimens. The purpose of the notch is to serve as a stress concentrator. The notch is probably the most critical part of .This article provides a discussion on the history and types of notch-toughness tests and focuses exclusively on notch-toughness tests with emphasis on the Charpy impact test. It reviews the requirements of test specimens, test machine, testing procedure and machine verification, application, and determination of fracture appearance and lateral .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

Notch test or V-notch test is a popular name used for the Charpy Impact Test. It is a highly standardized test which helps to measure the amount of energy which is absorbed by the notched sample when extreme pressure is applied to it. This energy is considered as a pathway to study the ductile-brittle nature of the sample. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve?

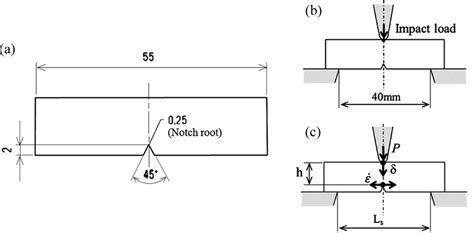

We would like to show you a description here but the site won’t allow us.The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine. To successfully perform a Charpy V-notch impact test, the following steps must be followed for accurate results: 1. Notch test specimens. The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar.

Key Standards for Sample Preparation and Impact Testing. ASTM E23: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. Scope: This standard specifies the requirements for notched-bar .

The Izod impact strength test is another form of notch toughness testing. It is similar to the Charpy V-notch test in that it uses a pendulum and a notch that acts as a stress riser. However, in the Izod impact strength test, the specimen is placed with the notch facing the pendulum. The pendulum strikes the specimen just above the notch. The .

IZOD test is vertical while Charpy tests are horizontal but both measure impact resistance. The main difference lies within a notch sample orientation during testing where in an Izod notched bar impact test, the specimen stands vertically with its notch facing towards the pendulum whereas, during charpy v-notch impact test ,the samples are placed horizontally . The impact engineers want to know when a material favours brittle fracture, some materials are ductile in a specific range of temperature, but they still fail like brittle material, why ? presence of stress risers, high rate of strain . , by bringing the notch they promote the condition of brittle fracture and the notch provides three .

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .The use of cylindrical notched specimens in impact testing was proposed by Philpot [S] in 1918. Although the cylindrical geom etry did not replace rectangular bars in impact testing, it did become popular for use in notched tension testing. The effect of notches on the tensile behavior of cylindrical steel specimens was described by Ludwik . The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount of energy absorbed by the specimen during fracture.Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

Izod impact test creates a V-shaped notch at the middle of the metal or a slight low point in the middle. The horizontal force applies on the upper tip to break the material and concentrate the force at the notch point. Remember one thing here— notch and force applications on the same material aspect.Purpose: The purpose of the current research is to quantify the impact of notch parameters viz. width, depth and central angle (perimeter length) on the fatigue life of UNS S32760 grade of super .

Impact testing is a complex and controversial subject, and one that is in the midst of change. These factors add challenge to selection of the most appropriate impact instrument for a processor's lab. . The notch size and shape are specified by the test standard. The purpose of the notch is to mimic part-design features that concentrate .One of the main differences from Charpy impact is that Izod impact testing is performed in two orientations on the same sample whereas the Charpy test is performed in the same orientation. Plastic samples are typically a 64 x 12.7 x 3.2 mm bar with a machined V-shaped notch.

notched bar pressure test

Jogos Santa Casa

use of notch in impact test|notched bar pressure test